Description

SIGNOR PIPE CORPORATION (SPC) is a well-known manufacturer in the industrial, municipal, agricultural/irrigation, domestic pipe markets.

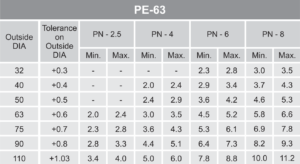

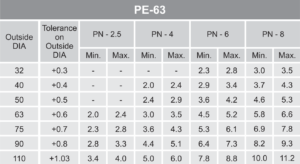

Proper raw materials with specified grades (PE63, PE80 & PE100) are selected for production and these polyethylene are polymerized in controlled environment thus producing PE pipes of high quality products, superiority on nature. Polyethylene (PE 100) pipes can carry potable water, waste water, slurries, chemicals, hazardous wastes, & compressed gases. In fact PE-100 is strong, extremely tough and very durable when compared to it preceding materials like PE-80, & PE-63 Grade. PE-100 Pipe has superior qualities in terms of mechanical and also other properties when compared to PE-80 & PE-63. The polyethylene material used for the manufacture of pipeline systems are classified and dimensioned by long term performance under hydrostatic pressure in accordance with IS 4984:2016. The design basis used in IS 4984:2016 for Pressure rating (PN) of PE Pipes in order to determine the minimum wall thickness for each diameter and PN rating provides for the steady and continuous application of the maximum allowable working pressure over an arbitrary period of 50 years. The selection of the long term hydrostatic design stress values (HDS) is dependent on the specific grade of PE and the pipe material service temperature.

The inherent flexibility of the HDPE Pipes provides this product with its inherent minimum pipe stiffness of 320 kPa or 210 kPa. The smooth inner wall provides longitudinal stiffness which enables alignment and grade to be maintained in the trench during installation.

Reviews

There are no reviews yet.